by Breathing Color

on January 30, 2024

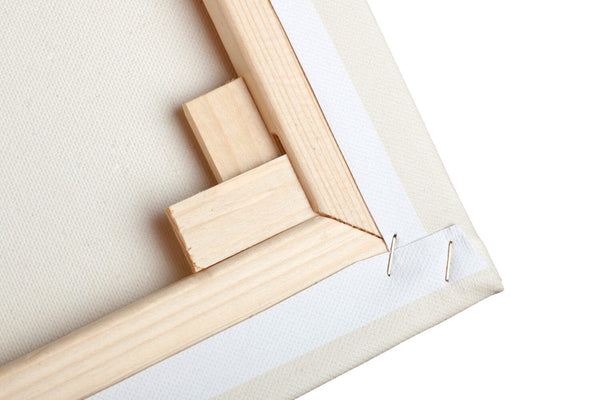

There are a variety of ways to stretch a canvas print. However, not every method...

by R. Carnie L

on January 24, 2024

Art isn’t just about the art anymore Digital printmaking has ‘leveled the playing field’ as...

by Michael Flanagan

on January 24, 2024

First things first, let’s define our terms so we know what we’re talking about. Unfortunately,...

by R. Carnie L

on January 24, 2024

Fine art printing is an art form in itself. Digital printing solutions have changed the...

by Jesus Marquez

on January 24, 2024

Canvas and paper have been staples in the fine art production and printing world since...

by Jesus Marquez

on January 11, 2024

The fine art printing industry has experienced a metamorphosis with the advent of digital technology...